Company

Industrial Vilassarenca manufacturers die-cast aluminium parts for the automotive sector.

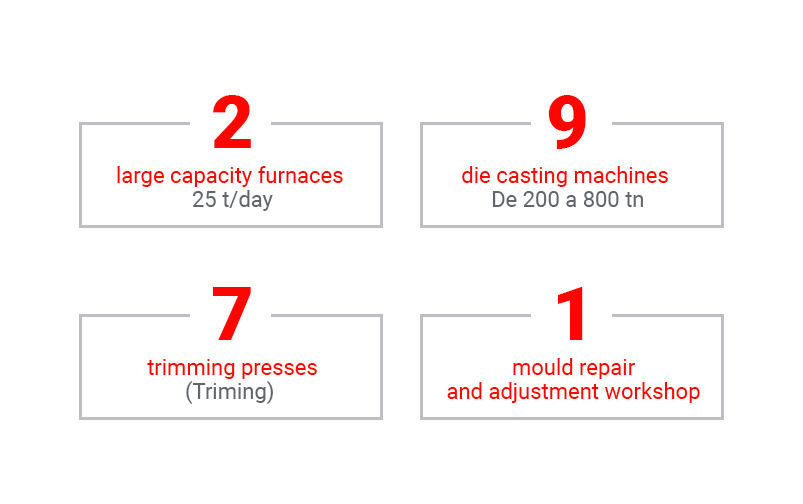

Our technology is based on cold chamber aluminium die casting at high pressure (HPDC).

We have been in the market since 1966, offering our services and innovation for the automotive industry, as well as the utmost quality for our clients. Thanks to ongoing improvements, innovation and development in our moulds, we are a benchmark in manufacturing high-tech parts for various applications in the automotive sector, without added phases of final machining.

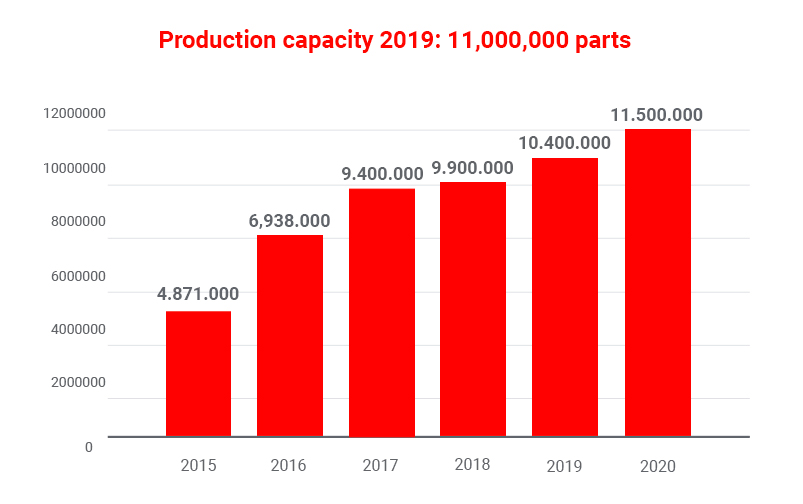

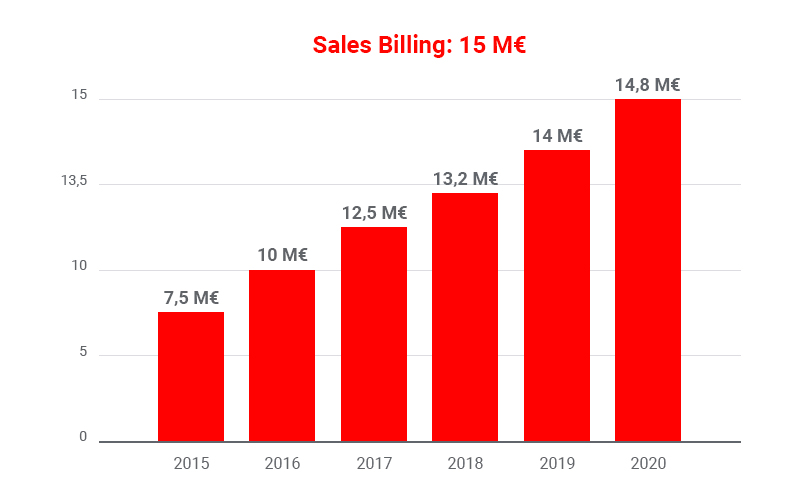

Our company in figures

Industrial Vilassarenca has an ambitious strategic plan, put in place in 2014, that has allowed the company to increase sales up to 170% over the past 5 years.

A history of growth

-

1966:

Industrial Vilassarenca got its start in Barcelona, specialising in manufacturing moulds for casting aluminium.

-

1969:

First die-casting machine to mass produce parts.

-

1988:

Move to Sant Cugat del Vallès.

-

1997:

MWK investment group joins shareholders, promoting internationalisation of the company.

-

2003:

Mould-making externalised, allowing the company to focus on development and mass production.

-

2011:

Founders buy back share from MWK. Launch ambitious strategic plan.

-

2014:

Sales up 20% from previous year. Facilities expanded, new die-casting machines added and staff hired, mainly in engineering and quality.

-

2015:

Sales up 30% from 2014. 2 new furnaces. New finishes and dispatch plant built in Sant Fost de Campsentelles.

-

2016:

Sales up 30% from previous year. New verification facilities launched. 1,000-m2 plot of industrial land acquired to expand facilities at main plant in Sant Cugat del Vallès.

-

2017:

Sales up 25% from 2016. 2 fully automated production lines added with the collaboration of Acció 10. With the highest tonnage to date.

-

2018:

Strategic plan launched, after all areas of the company stabilised. To maintain growth, the company begins searching for a new location with more space for business activities.

-

2019:

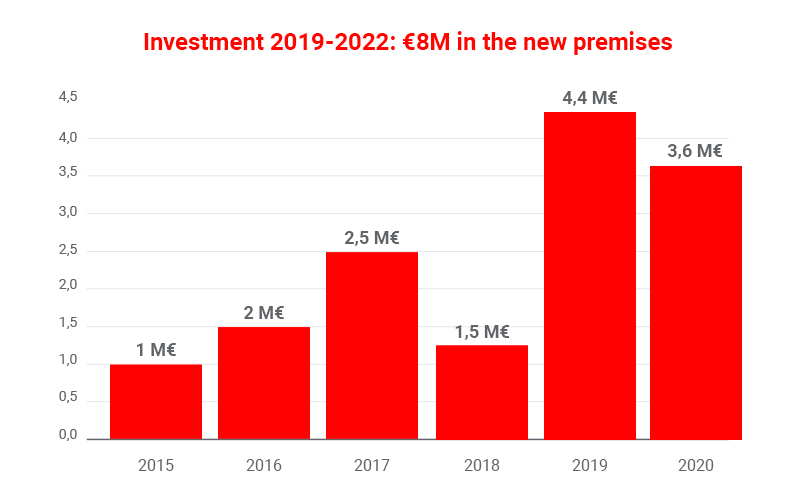

All production processes improved using tools like OEE. Facilities’ capacity increased. New projects acquired for electric vehicle. 13,000-m2 facility acquired to move all company activities.

Ongoing projects

-

2020:

Refurbishing the new facilities for Industrial Vilassarenca activities.

-

2020:

Relocating Vilados (verification centre) to the new premises.

-

2022:

Transferring production from Industrial Vilassarenca to the new facility, with prior approval from company clients.